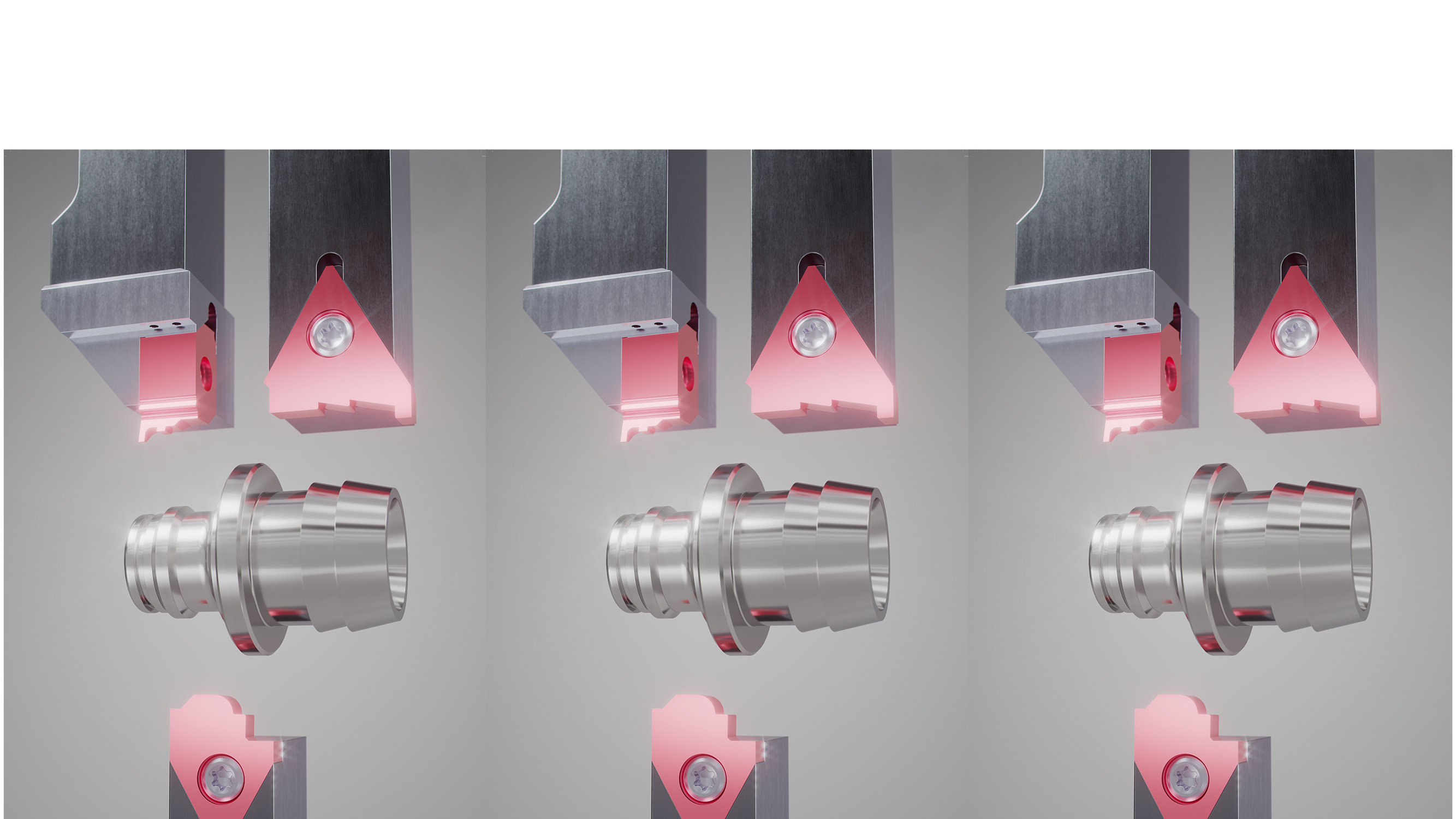

Precision and Efficiency in a Single Operation Thanks to Form Grooving Inserts

Form grooving inserts are designed to produce multi-stage geometries, radii, and transitions in a single cut – an efficient alternative to conventional grooving tools. This reduces:

- Machining time – fewer plunging operations, fewer tool changes

- Costs – shorter cycle times and long tool life

- Sources of error – fewer process steps and consistent dimensional accuracy

Especially in high-volume production and serial manufacturing, such as in the automotive industry, these savings are clearly noticeable.

Shorter Machining Times

A single form grooving insert replaces multiple plunging operations, reduces tool changes, and significantly lowers cycle times.

Fewer Sources of Error for Greater Process Reliability

The contour is precisely defined by the profiled tool. This minimizes tolerance deviations and ensures consistent dimensional accuracy.

Noticeable Cost Savings

Shorter process sequences and reduced downtime decrease both machine runtime and overall production costs.

Optimized Repeatability

Advanced carbide grades, precision grinding technology, and perfectly matched toolholder systems ensure long tool life and reproducible results.

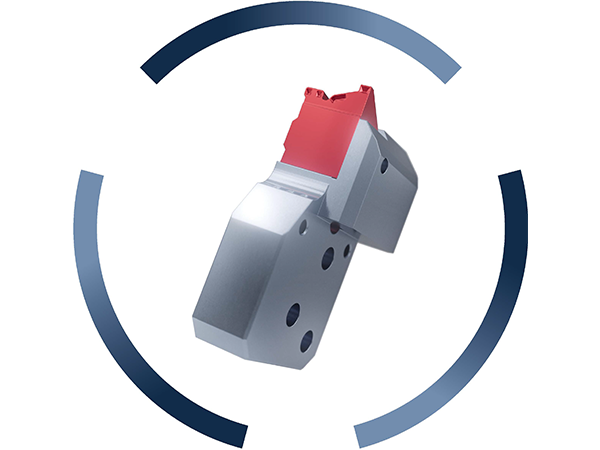

Precision From the Grinding Shop: Material and Manufacturing at MAS Carbide

Perfection is achieved in the grinding process. At MAS Carbide, precision indexable inserts are manufactured and finished in our grinding department with maximum accuracy. The result: dimensional tolerances in the micrometer range combined with consistently high surface quality.

To achieve this, we use exclusively proven carbide substrates with application-specific coatings, precisely matched to deliver optimized performance in your machining process.

Our Mission: Innovation Rooted in Tradition. For Over 40 Years

Practical Examples: How Precision Indexable Inserts Transform Everyday Manufacturing

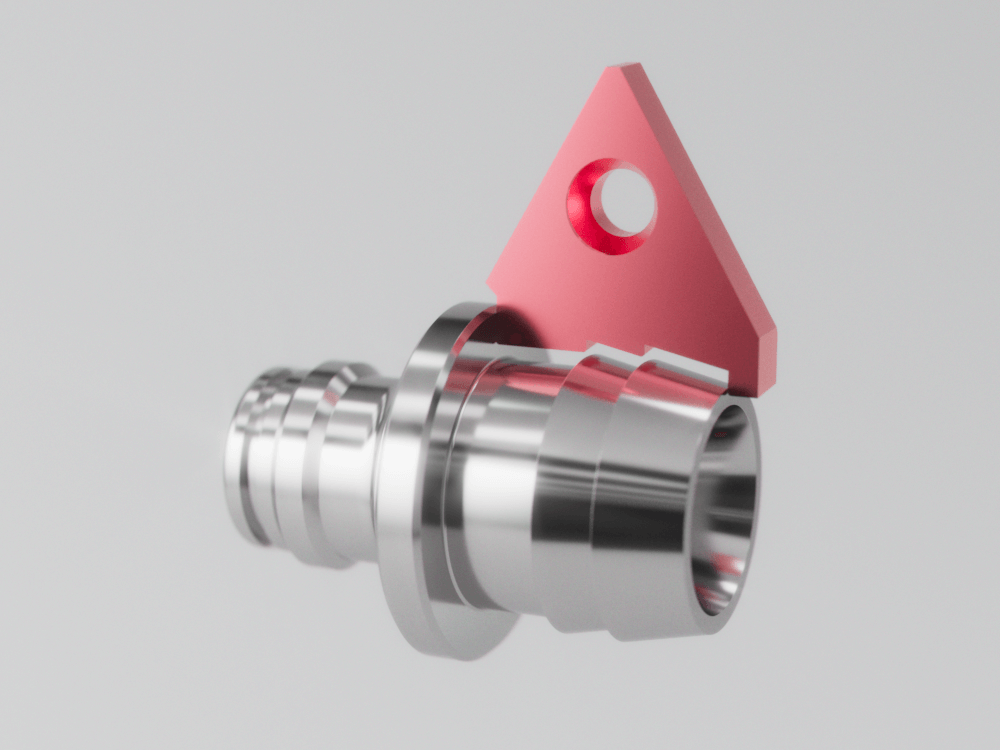

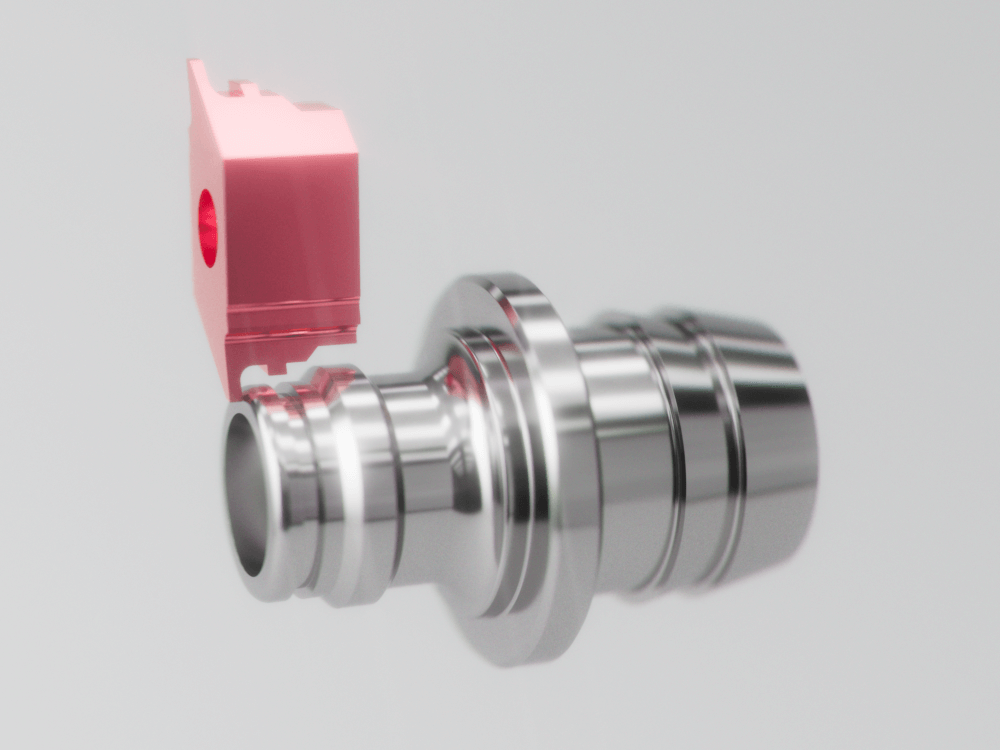

Example: Hose Adapter – Connection Side for Hose Coupling

Before:

Profile turning of the complete contour for the hose connection, requiring multiple cuts and resulting in long machining times.

Optimization:

The entire contour is produced using a form grooving insert – only a single cut is required.

Practical Impact:

- Reduced cycle time – instead of multiple passes, only one machining operation is needed.

- No burr formation on sealing surfaces – components leave the machine ready for assembly.

- Dimensional accuracy remains consistent, even at high production volumes.

Especially in large-scale production, this approach saves several hours of machine runtime per week and significantly reduces the need for rework due to dimensional deviations.

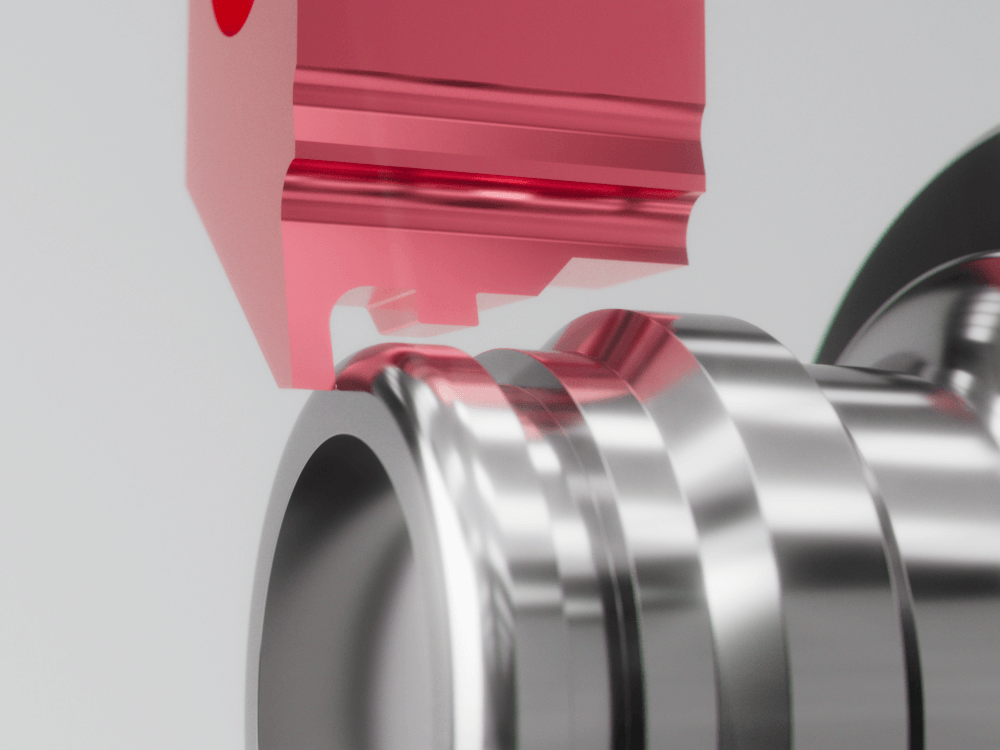

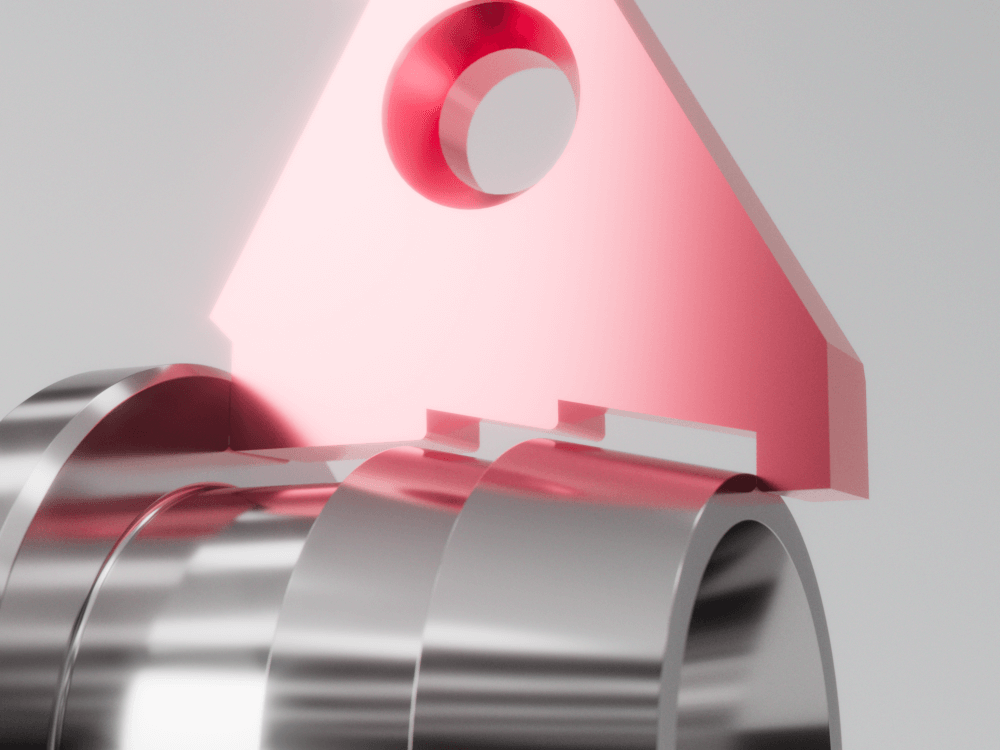

Example: Hose Adapter – Connection Side With O-Ring Groove

Before:

Profile turning in multiple passes, O-ring groove produced with a separate tool, resulting in inconsistent surface finishes.

Optimization:

The sealing contour is machined using a form grooving insert, including the O-ring groove and facing surface – completed in a single cut.

Practical Impact:

- Reduced machining time through elimination of multiple tool changes

- Stable process and lower susceptibility to production errors

- Reduced tooling costs by using a single tool

In serial production, consistent quality and short cycle times are critical. Both are achieved by eliminating tool changes and unnecessary splitting of cutting operations.

Optimize Your Process With MAS

MAS is your partner for highly efficient machining solutions, tailored technical consultation, and sustainable process optimization. Our experts support you in unlocking the full potential of your machining process.