Understanding wear and optimising the process

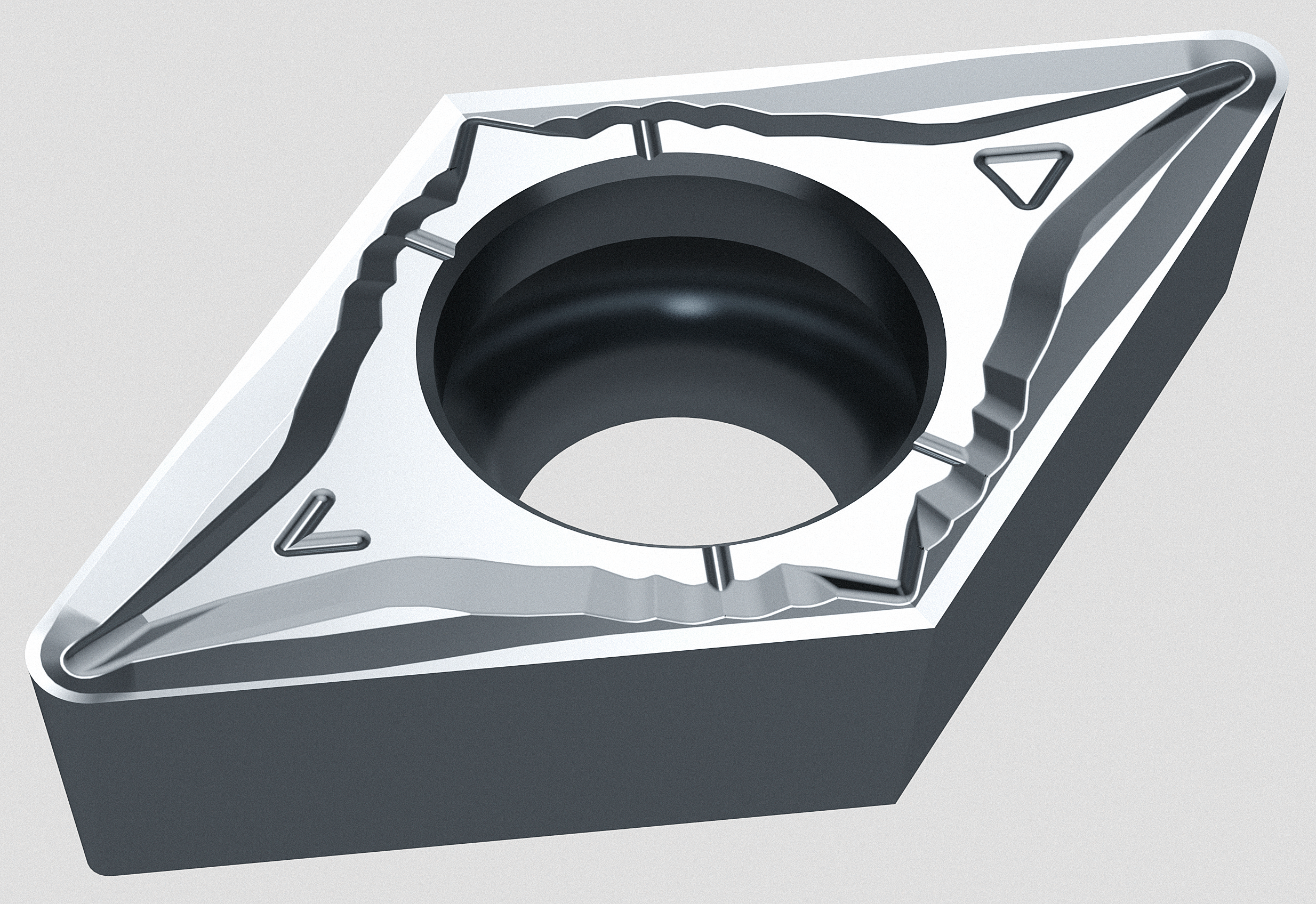

In modern machining technology, tool wear is one of the decisive factors for productivity, quality and cost-effectiveness. Indexable inserts are high-performance tools that are subjected to enormous forces and temperatures. Over time, every cutting edge wears out - but how quickly this happens depends on numerous influencing factors.

A certain amount of wear is unavoidable and even desirable as long as it remains controllable. Predictable wear enables a predictable tool life and stable production. Problems arise if the cutting edge is worn prematurely or unevenly - this can lead to dimensional deviations, poor surface quality, increased cutting forces or even tool breakage.

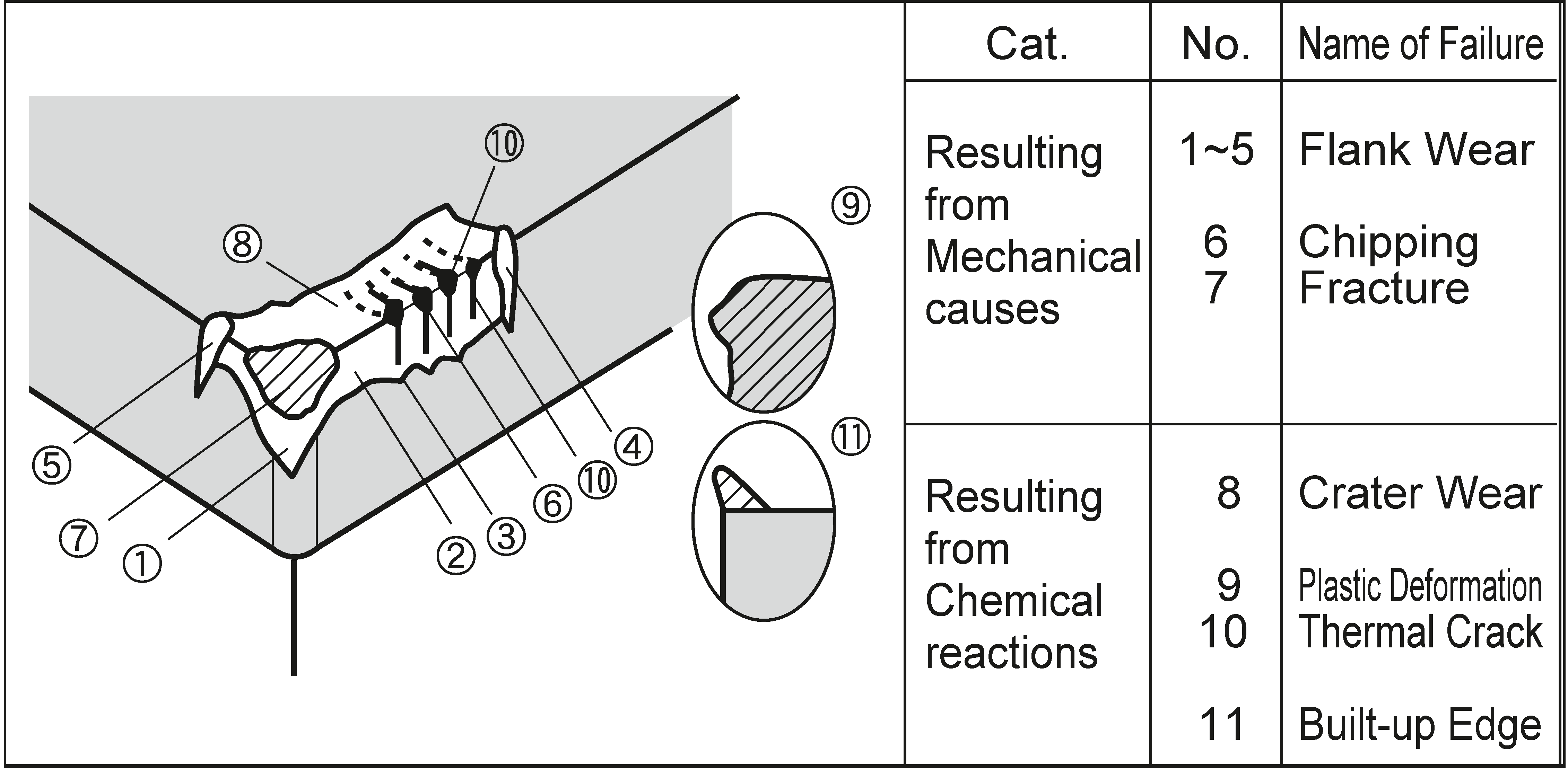

Not all wear is the same

In order to understand and minimise tool wear correctly, a distinction must be made between two levels:

Wear mechanisms – the physical and chemical processes that lead to wear of the tool. These include abrasion, adhesion, diffusion, oxidation, thermal stress and mechanical overload.

Forms of tool wear – the visible and measurable changes to the indexable insert resulting from the mechanisms. These include flank wear, crater wear, notch wear or cutting edge chipping.

One and the same wear mechanism can manifest itself in different forms.

At the same time, several mechanisms can act in parallel - for example, high abrasive wear can lead to flank wear, while diffusion wear increases crater wear.

Goal: Control, don't eliminate wear

Effective wear management does not mean preventing wear completely - that is impossible. Rather, it is about slowing it down, controlling it and utilising it economically. The following factors play a key role here:

- Optimised choice of cutting material and coating (carbide, CBN, PCD, ceramic, PVD and CVD coatings, etc.)

- Adapted cutting values (cutting speed, feed rate, cutting depth & cutting width)

Correct cooling lubrication strategy (continuous or dry, depending on cutting material) - Stable workpiece clamping & machine settings (to avoid vibrations and impact loads)

- Early identification & replacement of indexable inserts to avoid rejects and machine damage

In the following, we examine the most important wear mechanisms and forms in detail, explain their causes and show practical measures for optimising tool life. Because if you understand tool wear, you can control it - and that means fewer tool changes, higher quality and more economical production.

Process optimisation starts at the cutting edge

Reduce tool wear, optimise tool life and lower your production costs - with the right strategy. We analyse your process and optimise your production.

1. Wear mechanisms: Why and how do indexable inserts wear out?

The wear of indexable inserts is the result of various physical, mechanical and chemical processes. These wear mechanisms determine how quickly and in what form the cutting edge is worn. Several mechanisms can occur simultaneously or reinforce each other.

Abrasive wear - the ‘sanding effect’ of hard particles

Abrasive wear occurs when hard particles from the workpiece material (e.g. carbides, nitrides or cast scale) act like abrasive grains on the tool surface. These particles grind both on the rake face and the flank face of the tool and remove material.

Typical signs:

- Uniform material removal along the cutting edge (→ flank wear)

- Matt-appearing cutting edge with fine scratch marks

Amplifying factors:

- Hard or abrasive materials (e.g. hardened steels, cast iron, sintered material)

- Cutting speed too high

- Incorrect choice of cutting material

Reduction measures:

- Select harder cutting materials (CBN, PCD, carbides, cermet)

- Use wear-resistant coatings (TiAlN, Al₂O₃)

- Adjust the cutting speed

- Use adapted machining strategies

- Optimise the engagement ratio of the cutting edge

Adhesive wear - when the workpiece bonds with the cutting edge

Adhesive wear usually occurs with soft, elastic materials. The adhesive effect of these materials is increased by an unfavourable process temperature and pressure conditions. This can result in removed workpiece material particles adhering to the indexable insert and then tearing off again. Cutting material can also be torn off, which weakens the cutting edge.

Typical signs:

- Material welds on the cutting face (→ built-up edge formation)

- Rough or damaged workpiece surface

Amplifying factors:

- Soft, adhesive materials (e.g. aluminium, stainless steel, copper alloys)

- Unsuitable cutting speeds

- Unfavourable cutting edge or chip breaker geometry

Reduction measures:

- Select a suitable cutting speed

- Select more positive cutting edges

- Use polished cutting surfaces or coatings with high sliding properties

Diffusion wear - material exchange between cutting material and workpiece

Diffusion wear is a chemical process in which atoms are exchanged between the tool and the workpiece. As a result, the cutting material loses its stability, which leads to a weakening of the cutting edge.

Typical signs:

- Depressions or indentations on the rake face (→ scour wear)

- Increased cutting edge chipping

Amplifying factors:

- High cutting speeds and temperatures (> 800°C)

- Ferrous materials in combination with diamond tools (strong tendency to diffuse)

- Use of unsuitable cutting materials

Reduction measures:

- Use aluminium oxide coatings (prevent material exchange)

- Select suitable cutting material/workpiece combinations (e.g. diamond only for non-ferrous metals)

- Reduce cutting speed

- Cooling

Oxidation wear - when oxygen affects the tool

At high temperatures, cutting material components react with the oxygen in the environment and form oxide layers. These are often less stable than the original material and can peel off, weakening the cutting edge.

Typical signs:

- Oxide layers or material discolouration on the cutting edge

- Notch wear on the cutting depth line

Amplifying factors:

- High machining temperatures (> 700°C)

- Uncoated indexable inserts

- Machining of high-temperature alloys

Reduction measures:

- Select Al₂O₃ coatings or heat-resistant cutting materials

- Optimise cooling (continuous or completely dry)

- Reduce cutting speed

Thermal wear - when heat and cold break the cutting edge

Thermal wear is caused by extreme temperatures or temperature differences during the cutting process. If a hot tool is cooled abruptly (e.g. due to an irregular supply of cooling lubricant), stresses are created that lead to fine cracks. An excessively high process temperature can also weaken the cutting material, which favours plastic deformation of the tool cutting edge.

Typical signs:

- Fine cracks perpendicular to the cutting edge (→ comb cracks)

- Deformed or sunken cutting edge (→ plastic deformation)

Amplifying factors:

- Alternating cooling (e.g. intermittent lubricoolant supply)

- High cutting speed and feed rate

- Cutting materials with low thermal shock resistance

Reduction measures:

- Use cutting materials with high temperature resistance (cermet, ceramic, CBN)

- Use cooling either continuously or not at all

- Adjust feed rate or cutting speed

Mechanical wear - when the cutting edge fails under pressure

Mechanical wear occurs when the cutting edge is overstressed by excessive cutting forces or impact loads. This can lead to microcracks, crumbling or even complete insert breakage.

Typical signs:

- Small chipping on the cutting edge (→ Cutting edge chipping)

- Cracks parallel to the cutting edge (→ Fatigue fractures)

- Completely broken inserts

Amplifying factors:

- Excessively high feed rates or cutting depths

- Insufficient workpiece clamping or machine instability

- High alternating stresses such as heavy cutting interruptions

- Vibrations during machining

Reduction measures:

- Use tougher cutting materials or more stable geometries

- Optimise workpiece clamping and machine rigidity

- Reduce feed rate and infeed

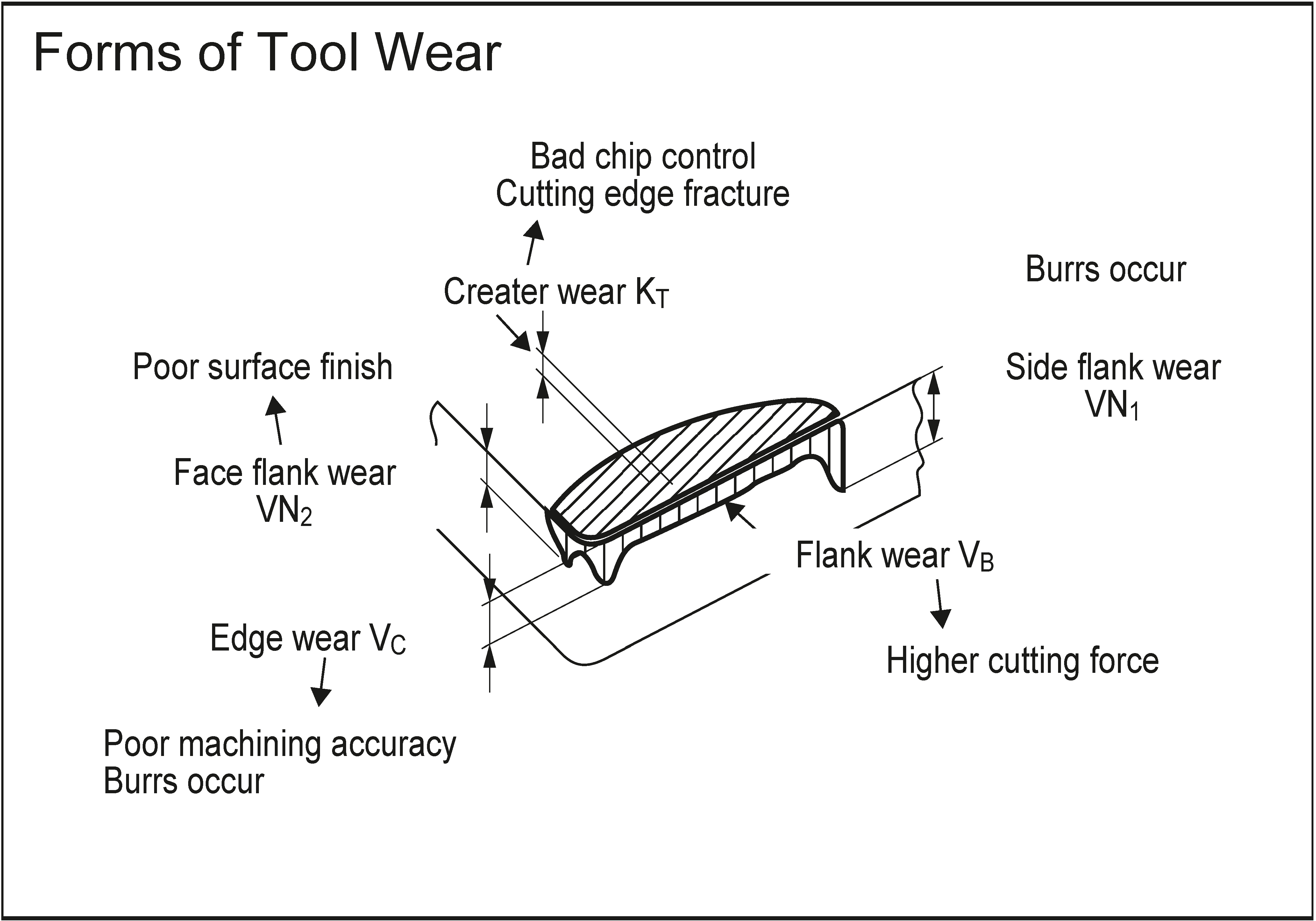

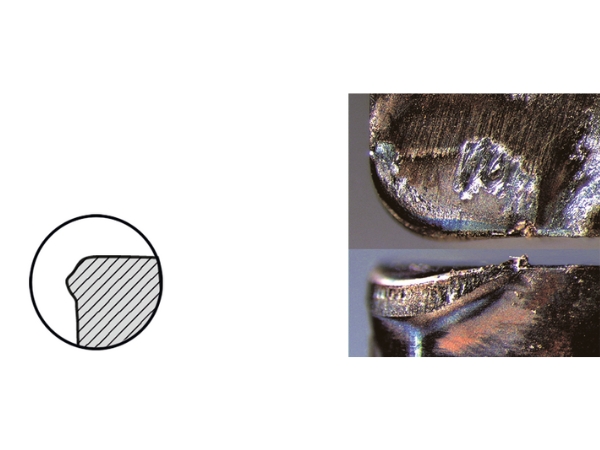

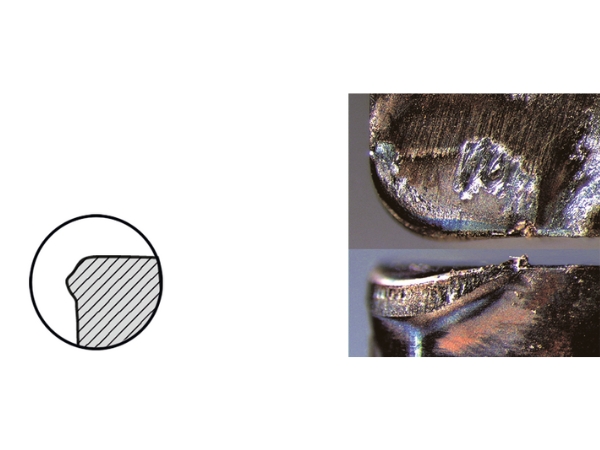

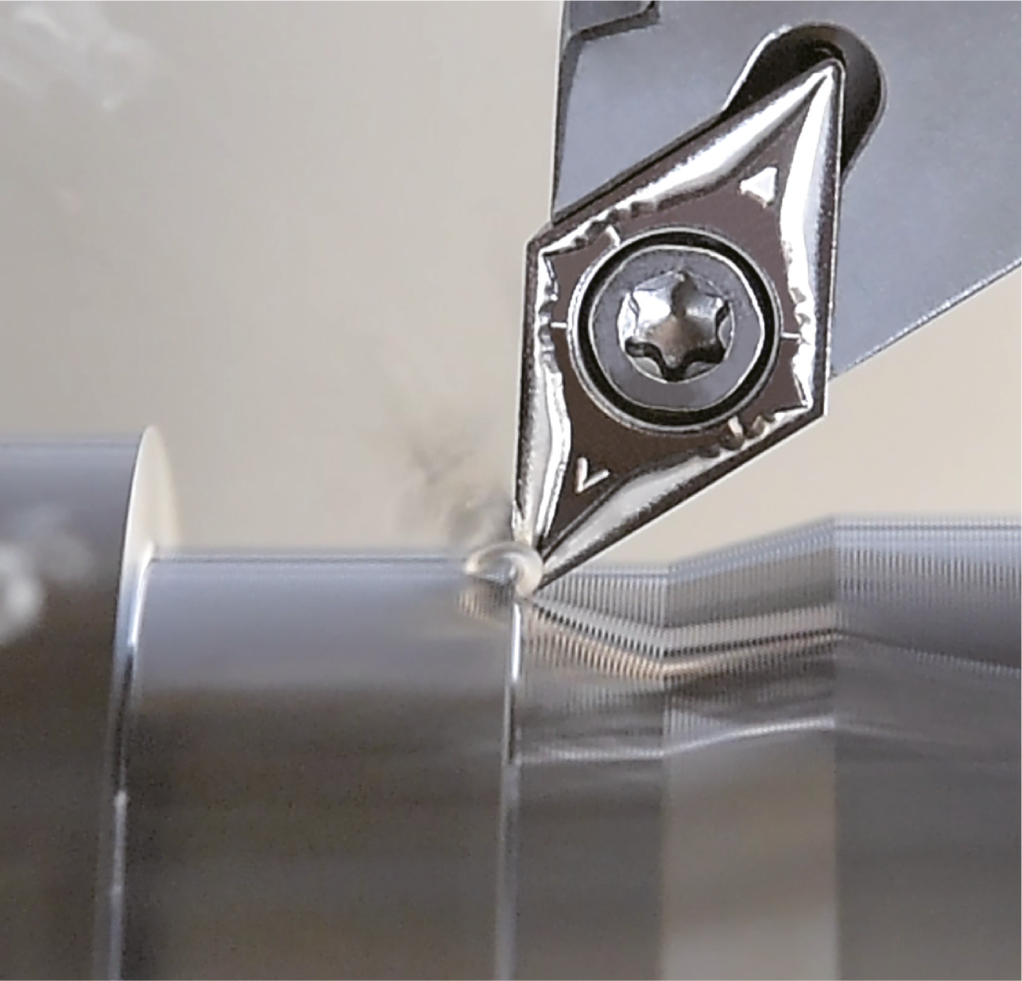

2. Wear patterns for indexable inserts

While the wear mechanisms describe the underlying processes that lead to wear, the forms of wear show how these manifest themselves on the cutting edge. The type of visible wear provides important information on which mechanisms are at play and which measures should be taken to optimise the service life of the indexable inserts.

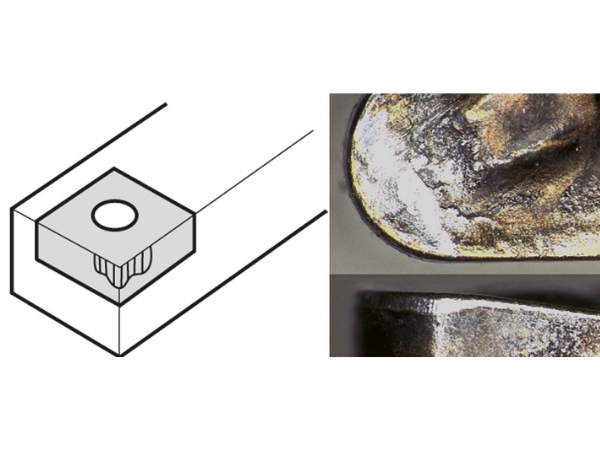

Flank Wear – Uniform Abrasion on the Clearance Face

Characteristics:

A continuous wear zone along the clearance face of the insert

Typically occurs during long-term, uniform wear processes

Often the main tool life criterion, as it develops gradually

Cause:

Abrasive wear due to hard particles in the workpiece

High cutting speeds intensify the effect

Consequences:

Dimensional inaccuracies and reduced surface quality

Increased cutting forces and heat generation

Solution:

✔ Use harder or coated inserts

✔ Lower cutting speed, increase feed rate if appropriate

✔ Select the correct cutting edge geometry

Flank wear is especially problematic in internal machining, where slender tools with long overhangs are used. This increases the risk of vibrations caused by flank wear.

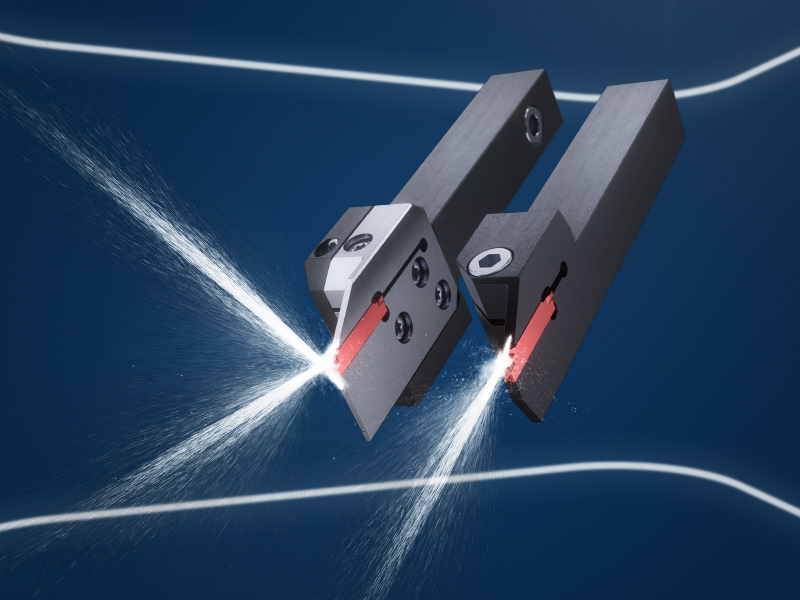

The IN©turn system from MAS features a cutting edge geometry optimized for both sharpness and edge stability. Combined with a high-performance coating, this reduces cutting forces and thus friction on the clearance face.

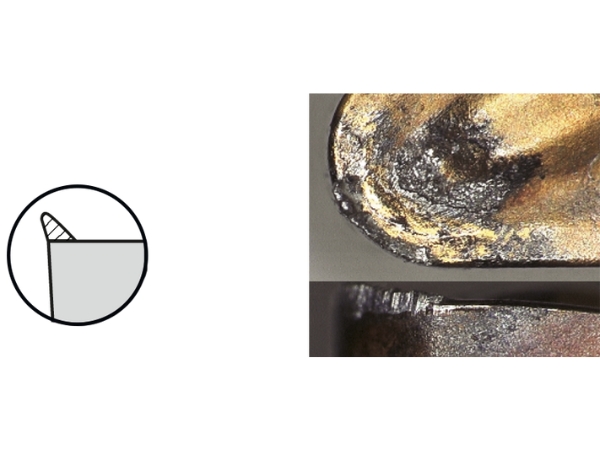

Crater Wear – Depression on the Rake Face

Characteristics:

- A visible crater or depression on the rake face of the insert

- Typically occurs in areas with high friction or heat generation

Cause:

- Diffusion wear: Material exchange between tool and chip

- Abrasive wear caused by chips sliding over the rake face

Consequences:

- Weakening of the cutting edge → risk of fracture

- Uncontrolled chip formation and poor dimensional accuracy

Solution:

✔ Reduce cutting speed

✔ Use harder or coated inserts (e.g. Al₂O₃, CVD coatings)

✔ Apply more positive cutting edge geometry for smoother chip flow

✔ Optimize cutting parameters and tool geometry

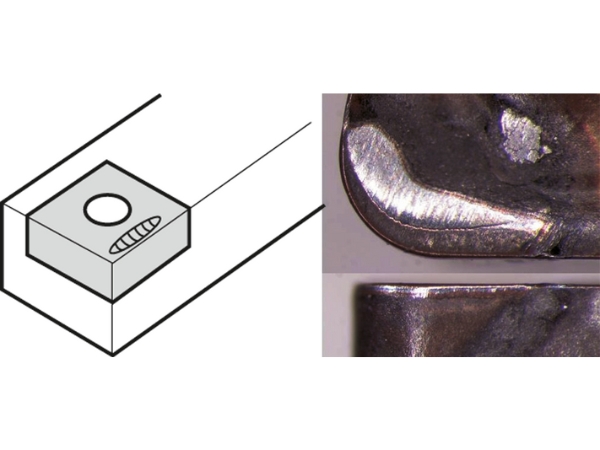

Built-Up Edge Formation – When the Workpiece Sticks to the Cutting Edge

Characteristics:

- Material build-up welded onto the cutting edge (often shiny)

- Irregular workpiece surfaces due to uncontrolled detachment of the built-up edge

- Inconsistent tool life

Cause:

- Adhesive wear: Workpiece material sticks to the cutting edge and solidifies again

- Improper cutting speed → heat input is unsuitable for the material being machined

Consequences:

- Irregular material removal → dimensional inaccuracies and poor surface finish

- Increased stress on the cutting edge → risk of edge chipping

Solution:

✔ Adjust cutting speed to suit the material

✔ Use more positive cutting edge geometries

✔ Choose polished cutting surfaces or coatings with improved sliding properties

Notch Wear – Grooving at the Depth of Cut Line

Characteristics:

- A pronounced notch where the cutting edge reaches its maximum depth of cut

- Particularly common when turning or milling materials with hard surface layers or high-alloy steels

Cause:

- Oxidation wear due to chemical reactions at the depth of cut line

- Abrasive wear from hard materials or casting skin

Consequences:

- Localized stress peaks → risk of edge chipping

- Uneven tool life along the cutting edge

Solution:

✔ Improve cooling to reduce oxidation

✔ Use more positive rake angles or alternative coatings

✔ Vary depth of cut to avoid localized overloading

Thermal Cracks – Fine Heat-Induced Cracks Perpendicular to the Cutting Edge

Characteristics:

- Very fine cracks running perpendicular to the cutting edge

- Often only visible under a magnifying glass or scanning electron microscope

Cause:

- Thermal wear due to repeated temperature fluctuations

- Improper cooling (e.g. sudden coolant supply during machining)

Consequences:

- Cracks weaken the cutting edge → risk of complete tool failure

- May develop into larger edge chipping

Solution:

✔ Use continuous or no cooling (avoid intermittent coolant supply)

✔ Choose cutting materials with high thermal shock resistance (e.g. cermet, ceramic, CBN)

✔ Adjust cutting speed to keep temperature peaks low

Plastic Deformation – When the Cutting Edge Gives Way

Characteristics:

- The cutting edge appears visibly sunken or deformed

- Often accompanied by discoloration due to overheating

Cause:

- Thermal wear from excessive temperatures

- Excessive mechanical load

Consequences:

- Irregular workpiece surfaces

- Cutting edge loses its geometry → dimensional accuracy compromised

Solution:

✔ Reduce cutting speed

✔ Use harder cutting materials or thicker coatings

✔ Adjust feed rate

Cutting Edge Chipping – Sudden Breakout Along the Edge

Characteristics:

- Small or larger chips on the cutting edge

- Often distributed irregularly

Cause:

- Mechanical wear due to high impact loads or vibrations

- Improper workpiece clamping

Consequences:

- Sudden tool failure

- Increased cutting forces → accelerated tool wear

Solution:

✔ Check workpiece clamping and machine rigidity

✔ Use a more stable cutting edge geometry

✔ Choose tougher cutting materials or coated inserts

Fatigue Fractures – When the Cutting Edge Gives In

Characteristics:

- Cracks running parallel to the cutting edge

- Often accompanied by prior microcracks

Cause:

- Mechanical wear due to fluctuating cutting forces

- Material fatigue under high loads

Consequences:

- Sudden loss of tool function

- Risk of machine damage from broken insert fragments

Solution:

✔ Use a tougher cutting material substrate

✔ Reduce feed rate and depth of cut

✔ Inspect tools regularly and replace them in time

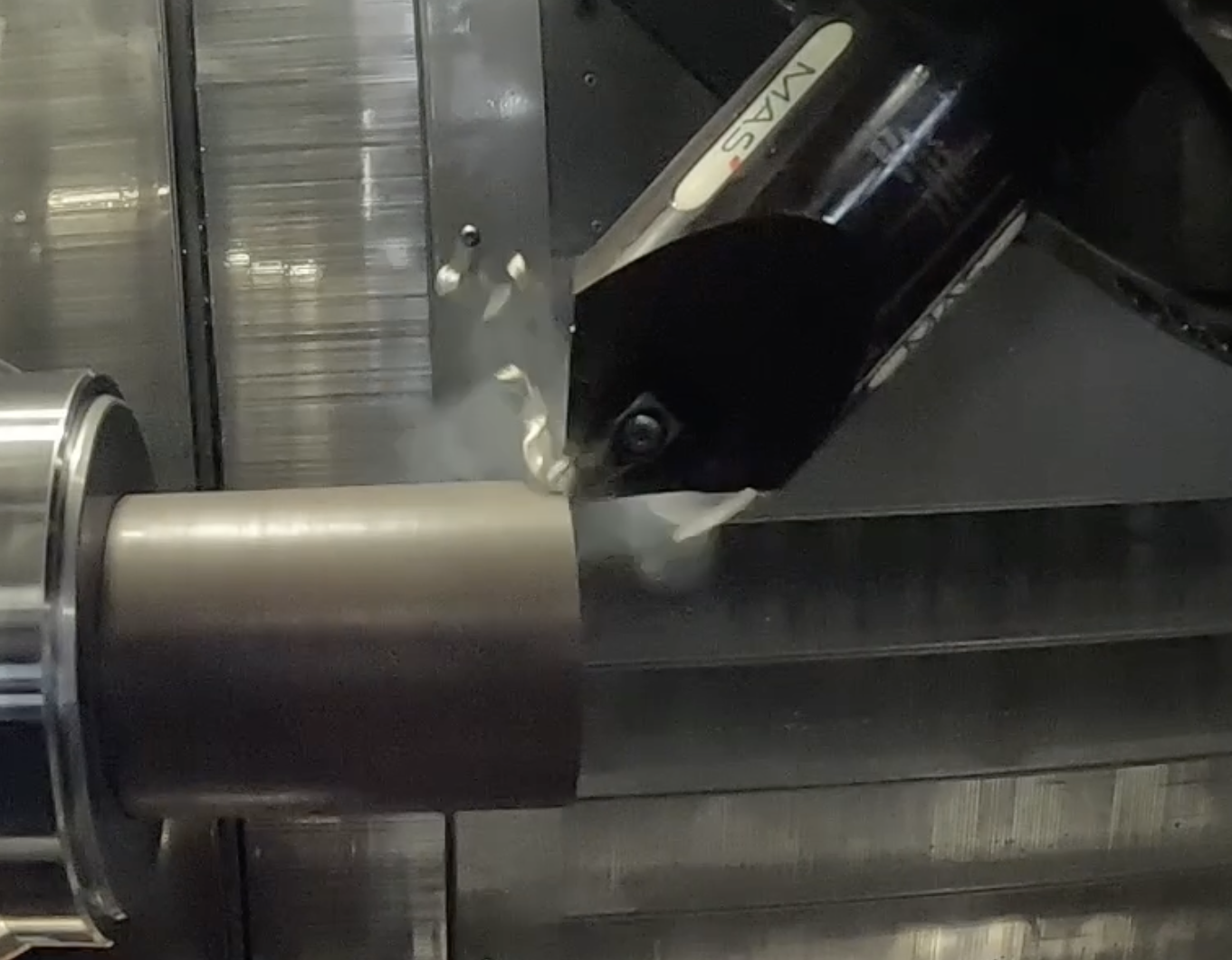

Chip Hammering - An Often Underestimated Cause of Tool Wear

Chip hammering is a mechanical wear mechanism that occurs when chips are not removed cleanly after shearing and hit the cutting insert or intermediate layer. This repeated impact can lead to chipping, flaking or micro-fractures on the cutting edge.

Why does chip hammering occur?

Turning or milling produces chips that are shaped differently depending on the workpiece material, cutting conditions and tool geometry. If chips do not flow away in a controlled manner, they can wind up, hit the tool or get caught, causing enormous forces to act on the indexable insert.

Chip hammering is particularly problematic:

- Long, cohesive chips that jam in the machining zone

- High feed rate & cutting depths, resulting in thicker, stronger chips

- Negative rake angles or unfavourable chip grooves that impede chip flow

Consequences of chip hammers for tool life

Repeated chip blows can cause microcracks or material chipping on the cutting edge. In the long term, this leads to

- Increased cutting edge chipping, as the tool body is subjected to additional stress

- Increasing cutting pressure and temperatures, which increases other wear mechanisms

- Poorer surface quality when broken off chip pieces hit the workpiece

Measures to avoid chip hammering

Targeted influence on chip formation

✔ Select the correct chip breaker geometry:

- For long chips: Narrower chip grooves or stronger chip breakers

- For short chips: Open, flatter chip grooves for better evacuation

✔ Control chip flow through optimised cutting edge geometry:

- More positive cutting angles → Easier chip removal

- Larger corner radii → Less chip flow interference

✔ Adjust cutting values:

- Vary the feed rate slightly to generate a uniform chip flow

- Select the cutting depth so that chips do not rest on the tool cutting edge

Prevent chip impact

✔ Adjust the setting angle to direct the chip flow in a different direction

✔ Use high-pressure cooling (HPC) to actively blow chips away

✔ Use air or MQL to keep chips away from the tool

Recognise wear. Improve processes.

Every type of wear has its cause - and a solution. Optimise your machining specifically for maximum tool life.

3. Strategies for reducing tool wear

Wear is an unavoidable part of machining - but it can be specifically controlled and minimised. The right combination of cutting material selection, cutting value optimisation and process adaptation can maximise the service life of indexable inserts and significantly improve economic efficiency.

Selection of the optimum cutting material

The service life of a cutting tool depends largely on the cutting material. The right choice can significantly reduce abrasion, diffusion and thermal wear.

Tip:

- For abrasive materials: Select CBN or PCD

- For high temperatures: CBN or ceramic

- Against chemical wear: CBN

- For adhesive materials (aluminium, stainless steel): Coated carbides or cermet

| Cutting Material | Advantages | Application Area |

|---|---|---|

| Carbide (HM) | High toughness, good wear resistance | Standard machining, steel, stainless steel, cast iron, aluminum, non-ferrous metals |

| Cermet | High hot hardness, low adhesion | Finishing operations, hard steels |

| CBN (Cubic Boron Nitride) | Extremely hard, resists diffusion wear | Hard turning, hardened steels, heat-resistant alloys, cast iron, sintered metals |

| PCD (Polycrystalline Diamond) | Maximum wear resistance, no diffusion wear | Aluminum, non-ferrous metals, fiber-reinforced plastics |

| Ceramic | Heat-resistant, resists notch wear | Heat-resistant alloys, cast iron |

Optimization of Cutting Material Coatings

Coatings protect the cutting material from abrasive, adhesive, and thermal wear.

Tip:

- To avoid adhesive wear → use TiN or polished coatings

- To minimize abrasive wear → use TiCN or Al₂O₃

- To reduce thermal stress → use TiAlN or Al₂O₃

| Coating | Properties | Application Area |

|---|---|---|

| TiN (Titanium Nitride) | Reduces adhesion, increases toughness | Stainless steels, aluminum, copper |

| TiCN (Titanium Carbonitride) | Harder than TiN, high abrasion resistance | Steels, non-ferrous metals |

| Al₂O₃ (Aluminum Oxide) | Resistant to high temperatures | Heat-resistant steels, cast iron |

| TiAlN (Titanium Aluminum Nitride) | High thermal resistance | Dry machining, carbide machining |

Adjustment of Cutting Parameters: Speed, Feed, Depth of Cut

Incorrect cutting parameters are one of the most common causes of excessive tool wear.

Tip:

- High cutting speed → increases diffusion and crater wear

- Low cutting speed → increases built-up edge formation

- Feed rate and depth of cut must be well coordinated

| Type of Wear | Cause | Solution |

|---|---|---|

| Flank wear | Cutting speed too high | Reduce speed, slightly increase feed |

| Crater wear | High temperatures / diffusion | Reduce speed and feed, use Al₂O₃ coating |

| Built-up edge | Cutting speed too low | Increase speed, use polished cutting edges |

| Notch wear | Cutting speed too high or too low | Adjust speed, vary depth of cut, select a more positive geometry |

| Thermal cracks | Alternating temperatures | Apply consistent cooling or switch to dry milling |

Impact of Cooling and Lubrication

Coolants and lubricants (cutting fluids) play a major role in controlling temperature and removing chips.

When is cooling recommended?

- Reduces adhesion in materials like aluminum and stainless steel → prevents built-up edge formation

- High-pressure cooling helps with chip evacuation and prevents surface deterioration

When is dry machining better?

- Prevents thermal cracking (e.g. with ceramic cutting materials)

- Reduces thermal shock → helps avoid tool breakage

Tip:

- Always ensure continuous coolant supply when cooling is used

- Dry machining is recommended for CBN and especially for ceramic tools to avoid thermal shock

- For reliable internal cooling, innovations like PSI©turn can be beneficial

Optimization of Tool Geometry

The cutting edge geometry influences cutting forces, chip formation, and heat generation.

Tip:

- For hard materials (cast iron, hardened steels) → use stable geometries with negative rake

- For soft materials (aluminum, stainless steel) → use sharp, positive rake edges

| Geometry | Advantages | When to Use |

|---|---|---|

| Positive rake | Reduces cutting forces | For soft or adhesive materials |

| Negative rake | High stability, long tool life | For hard materials, cast iron, titanium |

| Wiper inserts | Improved surface finish | For finishing or high-feed machining |

| Large corner radius | Lower point load | For high feed rates and stable cutting conditions |

Optimizing Machine Rigidity & Workpiece Clamping

Vibrations and unstable clamping increase mechanical wear and may cause cutting edge chipping or tool breakage.

Tips to Prevent Tool Breakage:

✔ Use rigid workpiece clamping → prevents uncontrolled vibrations

✔ Check machine accuracy → minimize spindle play

✔ Choose the right tool holder → reduces micro-vibrations

4. Trends in Tool Wear Management: The Future of Indexable Insert Technology

Technological advancements are fundamentally reshaping the machining industry.

Where tool wear was once monitored through fixed tool life intervals or manual inspections, today's innovations — including digital technologies, new cutting materials, and sustainable production strategies — enable intelligent and cost-effective control of the entire tool lifecycle.

Digital Wear Monitoring & Predictive Maintenance

Modern indexable inserts and tool holders are increasingly equipped with sensors that capture real-time data on temperature, pressure, and vibration. This information is fed directly into CNC controls or cloud-based analytics platforms, where AI algorithms assess tool condition and predict wear. As a result, tool changes can be precisely scheduled, and unplanned downtime is significantly reduced.

Artificial intelligence is fundamentally transforming machining. Machine learning analyzes large datasets, identifies wear patterns, and automatically adjusts cutting parameters. This enables dynamic process control, where feed rate, cutting speed, and depth of cut are optimized in real time to minimize tool wear.

Predictive maintenance makes tool management more accurate:

Instead of relying on fixed tool life intervals, each tool is used to its full potential. Modern CNC machines operate increasingly autonomously — AI-driven control systems plan tool changes more efficiently and optimize machining strategies without human intervention. The result: greater machine availability and reduced tooling costs.

Advancements in Cutting Materials & Coatings

New high-performance coatings such as AlTiN and AlCrN offer even greater heat resistance and are ideal for high-speed machining. Nanocoatings combine multiple protective mechanisms and, in some cases, can even partially self-heal. For non-ferrous metals and aluminum, diamond-like carbon (DLC) coatings create extremely smooth chip surfaces and effectively prevent built-up edge formation.

Cutting materials are also evolving:

While CBN and PCD remain the go-to solutions for maximum tool life in abrasive materials, increasing research is focused on sustainable alternatives to cobalt-bonded carbides.

Sustainability & Recycling of Indexable Inserts

Machining must become more sustainable — and manufacturers are increasingly implementing recycling programs for carbide and CBN tools. Reconditioning reduces raw material consumption and lowers CO₂ emissions. At the same time, the production of indexable inserts is becoming more energy-efficient through the use of resource-saving coating technologies and cobalt-free binders.

Another step toward sustainability is the growing use of dry machining and minimum quantity lubrication (MQL), both of which drastically reduce the consumption of cutting fluids.

Outlook: The Next Generation of Tooling Technology

The future of indexable insert technology lies in the combination of intelligent, self-optimizing processes and sustainable materials.

Digital monitoring, next-generation coatings, and AI-driven process control will further reduce tool wear and enable more cost-efficient manufacturing.

Fully automated CNC systems, longer-lasting cutting materials, and resource-efficient production methods are no longer distant visions — they are already being implemented in industrial settings.

Those who embrace these innovations early not only gain a competitive economic edge, but also ensure long-term success in an increasingly digital and sustainable manufacturing landscape.