Our tools set the standard in medical technology

Medical instruments require uncompromising quality—every edge, every engraving, every surface must be perfect. We combine certified quality with innovative solutions to guarantee maximum precision, service life, and process reliability.

See for yourself how a surgical hammer made of stainless steel is created on a DMG Mori NTX 2500—in a single pass!

ISO 9001 Certified

Our tools are manufactured according to the highest quality standards and undergo rigorous inspection processes. ISO 9001 certification ensures consistent precision, process reliability, and traceability – a crucial factor in machining.

High-Precision Micro Tools for the Finest Details

For dental implants, fine drilling, or micro-machining, we rely on ultra-precise tools starting from 0.1 mm in diameter – featuring specially developed cutting materials and coatings for longer tool life and maximum accuracy.

Development of Custom Tool Solutions

Every medical application is unique. We design tailor-made special tools precisely adapted to your requirements – for maximum efficiency and process reliability.

High-Performance Coatings for Maximum Tool Life

Especially when machining abrasive and hard-to-cut materials such as titanium and cobalt-chrome, the right coating can make all the difference. High-performance coatings ensure fewer tool changes and higher productivity.

Maximum Burr-Free Machining – No Reworking Required

Our tools minimize burr formation during the machining process itself. This saves time-consuming rework and reduces the risk of component contamination – a key factor in medical technology.

Member of VDMA – Medical Technology Division

As an active member of the VDMA Medical Technology Association, we actively shape the future of the industry. For you, this means certified quality, pioneering innovation, and a partner who understands and anticipates the industry’s requirements.

Rudischhauser: 8× longer tool life, over 50% lower costs

During the turning operation of a medical screwdriver made from Custom® 465, our customer Rudischhauser faced major issues with their existing machining tool.

An extremely short cutting-edge tool life in the roughing process, along with pronounced dimensional fluctuations, led to a high scrap rate.

Through our collaboration, we increased tool life from 7 minutes to 57 minutes while maintaining consistent, stable part quality.

Our Coorporation Partners

HB microtec GmbH & Co. KG is a technologically leading manufacturer of drilling tools for precision components made from hard-to-machine materials.

With MAS Carbide, we strengthen our expertise in form-turning and precision indexable inserts and strategically expand our manufacturing capabilities.

Perfection Is No Coincidence – Systematic Process Optimization

Top quality in medical technology is no coincidence – it’s the result of a perfectly optimized manufacturing process. But how do you unlock the full potential of your production? That’s exactly where MAS comes in: we analyze, consult, and optimize every step of your machining process to maximize productivity, precision, and cost efficiency.

Our approach: tailor-made process solutions for your production. For less waste, faster throughput, and a stable, economically efficient manufacturing process.

Innovative Strength for Medical Technology

NCB100 – The Revolution in Medical Machining

NCB100 is the first binder-free CBN grade in which the CBN crystals are directly bonded to each other. Developed for the highest demands, it delivers excellent surface quality, extremely long tool life, and maximum process stability – especially when machining hard-to-cut materials such as cobalt-chrome and titanium.

Thanks to its binder-free structure, contamination of components with cobalt is reliably prevented – a decisive advantage for sensitive medical applications.

The Titanium Specialists: AC9000 Series by Sumitomo

PVD-coated carbide inserts (AC9115T / AC9125T) with an optimized substrate, specifically designed for turning titanium alloys. Engineered to withstand high temperatures and adhesion tendencies – ensuring long, stable tool life and excellent surface finishes.

The Specialists for Exotic Materials: AC5000S Series by Sumitomo

PVD-coated carbide inserts for high-strength, hard-to-machine materials such as cobalt-chrome, nickel-based alloys, and demanding stainless steels. They combine high wear resistance with toughness – ensuring process reliability, even under interrupted cutting conditions.

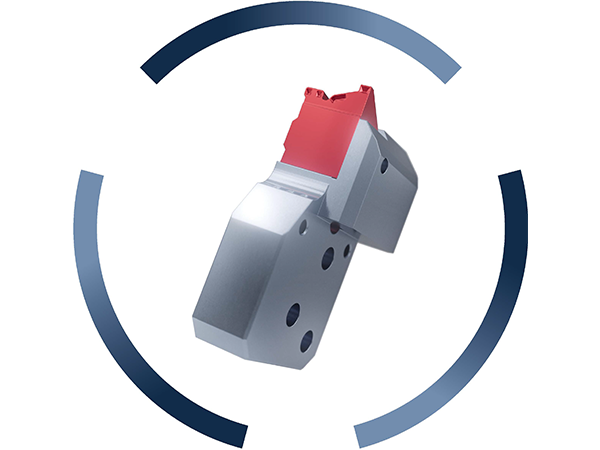

The Specialists for Swiss-Type Precision: MAS SWISS©line

Our modular tool and holder system – ideal for complex, delicate components, from implants to surgical instruments.

With maximum clamping stability, low-vibration machining, and a compact design, SWISS©line guarantees absolute repeatability, perfect surface finishes, and short setup times. Precision without compromise – especially when working with hard-to-machine materials such as titanium or cobalt-chrome.

SWISS©line U2 & U3

The U2 and U3 variants allow parting widths starting at just 0.3 mm – perfect for ultra-fine structures in miniature components.

✓ Maximum contour accuracy for the smallest dimensions

✓ Process reliability even with high-strength materials

✓ Ideal for medical implants and micro components

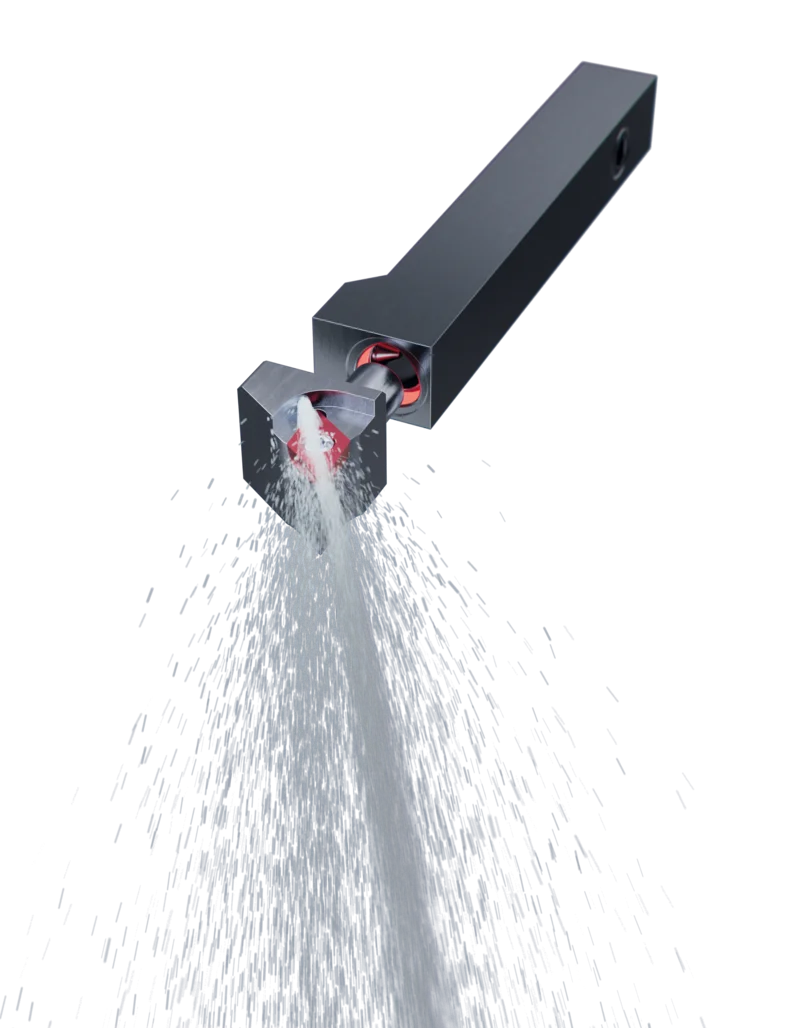

PZ©turn – Quick-Change System with Integrated Cooling

Our PZ©turn quick-change heads and holders come standard with internal cooling right up to the cutting edge – ensuring optimal chip evacuation, reduced heat generation, and superior surface finishes.

✓ Internal cooling integrated as standard

✓ Reliable performance even with hard-to-machine materials

✓ Quick-change system for minimal setup times and maximum repeatability

IN©turn – Micro-Machining for the Smallest Holes & Structures

Our IN©turn technology enables internal machining from as small as 0.2 mm in diameter – ideal for precise, delicate medical components.

✓ Perfect for dental implants and fine drilling

✓ Minimal heat generation – no microcracks or material stress

✓ Flexible use with just one holder system

MAS Carbide: Precision Contours with Form-Turning and Precision Inserts

Our form-turning and precision inserts enable burr-free cuts, outstanding dimensional accuracy, and perfect surface finishes — all in a single operation.

✓ Individually optimized cutting-edge geometries

✓ Advanced carbide substrates

✓ State-of-the-art coating technologies

✓ Reliable performance even with hard-to-machine materials

Our Mission: Innovation Rooted in Tradition. For Over 40 Years.

Redefine Precision

Medical technology demands perfection – and that’s exactly what we stand for. Whether it’s high-strength materials, delicate structures, or maximum process reliability: MAS is your partner for highly efficient machining solutions, individual consulting, and sustainable process optimization.